MUSTANG STORIES

|

Texas Shriners!

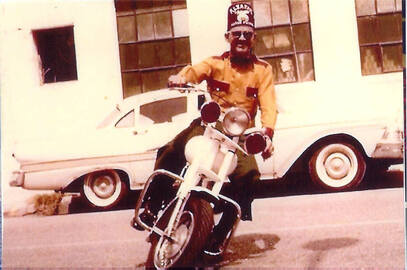

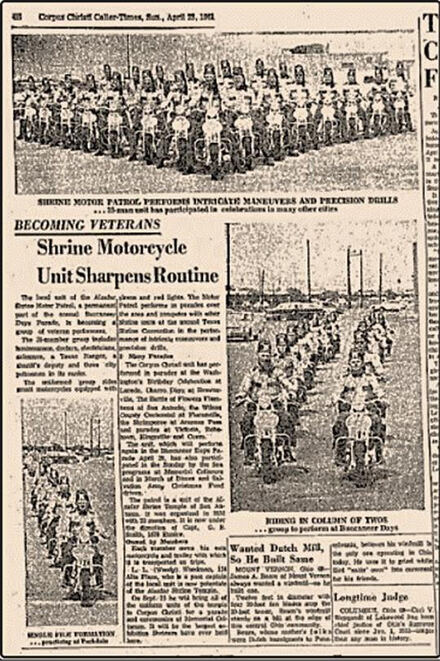

By LeeRoy Until the availability of new/premo used Mustangs and/or adequate parts to maintain available units, the Alzafar Shrine Temple (San Antonio, TX) had a Motor Patrol located in Corpus Christi, TX. They used Mustang Motorcycles painted in gloss white with chrome spoked wheels, Shriner emblems, red “police” lamps and a flywheel driven siren. Here’s a photo of my dad on his cycle in Circa 1965 practicing figure-8 riding for upcoming parade performance. The Shriners in Corpus Christi would soon become a separate temple named Al Amin and he would be their first elected Colonel of the Motor Patrol. Unfortunately, by then, they would have to transition to readily available Hondas for their team. We sold this cycle in late 1971 for $500. Here’s the article from the 21APR1961 Corpus Christi Caller-Times newspaper; as I said it’s a bit fuzzy but you can see how many Mustangs these gentlemen had acquired and rode for so many years! The article described them as a 25-man unit. The most complicated formation that they performed was a “double-figure 8” where they had four motorcycles crossing simultaneously in the middle of the 8 at close intervals without touching. Talk about synchronization! Parade crowds loved them! Of course, they would also ride into the beginning of the Shrine Circus performance on opening day. They performed at parades around the state so most had special built trailers that could accommodate up to three cycles to help with logistics. The motorcycles were adorned with a Shrine emblem on each side of the gas tank and on the metal support between the seat and fender at the back. A larger decal had the Shrine emblem with the words “Alzafar Temple” above it and “Motor Patrol” below it (the font resembled scimitar swords). The next time I’m back at my Mom’s house in Corpus Christi, I’ll try to get you a picture of my dad on his cycle in full dress uniform (gold lame jacket and black pants with fez) – it’s a full profile shot so you can see the livery it’s painted in. Oh, one small note that I left out. Because the cycles were equipped with red lights and sirens, all the group had to be sworn in as Special Sheriff Posse Deputies to legally operate them on a public roadway back then. Article about LeeRoy Lance Sr. submitted by his son LeeRoy Lance Jr. Thank you for the article LeeRoy! Progress By Jim Cavanaugh When the Mustang group moved from the Brand Boulevard location, and joined us at the Colorado Boulevard plant, things got a little cozy. Until then, we had the entire assembly building to ourselves, dedicated to producing the various engine models. It might surprise you to know that Mustang was not our best customer. Whiteman Enterprises, located nearby in Pacoima, California , was our largest customer who used the engines for their cement buggy and power trowel. Garbro, (Garlinghouse Manufacturing) followed, located in the Los Angeles area who also manufactured a cement buggy and supplied us with the solid disc wheels that they used on their heavy duty wheel barrel. Garbo’s version of the Model 75 engine was unique and different. They supplied us with a fabricated steel engine base that put the engine on a 45 degree angle. It had a large bushing welded on the lowest end as a pivot point which was used as a clutch, whereby the engine would pivot and tighten or loosen the friction drive. Because the engine was on this severe angle, they also supplied a special oil pump, made from aluminum round stock. Also, a 45 degree carburetor manifold to allow a side draft carburetor. This 45 degree unit always intrigued me and I always had a desire to install this unit in a Mustang. Actually, Mustang was about our fourth largest customer at the time. Anyway, when the Mustang group set up business right next to our assembly conveyor belt I watched the operation since it was right under my nose. At that time, I was foreman of the engine division and had plenty of things to do, but I could not help notice that some of the assembly operations next to us seemed strange in my mind. The biggest problem I felt was the two very long benches about 24 inches off the floor. Each had fixtures for five units. I noticed that every assembler had to climb over or walk around this bench arrangement to work on the other end of the bike. Talk about lost motion! Then, after the bikes were completed, they had to take several people to lift the units over the bench to set it on the floor. No doubt this alone caused back injuries. At that time I could not say anything since I worked for Gladden Products division and had no business butting in. Later, as time went on and the engine production slowly dwindled, I was put in charge (reluctantly I’m sure). I pleaded my case to Howard Forrest. Usually management never paid much attention to my suggestions or comments but Howard was always interested in my opinion. I explained that if each assembly station had a pedestal arrangement, whereby, the assembler could walk completely around the unit in progress, a more efficient production would result. Not only did Howard agree, he designed the pedestals and drew up the drawings and ten fixtures were built and bolted to the concrete floor. I never received any credit for this major improvement. I guess it was just part of my job. — Jimbo My Mistake By Jim Cavanaugh Funny thing happened when I started my Thoroughbred last week. After warm-up it ran awful. It seemed to run fair at low speeds but would not accelerate. It just popped, back fired and farted. I know it sat for a good while since I last used it. First thing I thought was the fuel was too old. I removed the gas cap and put my nose in and it passed the smell test. Next, I removed the Dellorto and expected to see the float chamber full of varnish. Nope, it was clean! I carefully blew out all the passages, put it back on the bike and it was still “shooting ducks”! What’s going on here? I built thousands of Mighty Mustangs during my first career and never had this problem. I removed the flywheel and checked the points, which showed some wear but not defective. I removed the ignition coil and looked for oblivious breaks in the primary wire. I tested the coil with my volt meter and it checked out OK. ( if anyone is interested in learning how to check the ignition coil, let me know) I installed new points & condenser and retimed it. I checked the compression and it was great! For sure I thought it would run much better. It started on the first kick but after warm up I was still duck hunting! What is happening? At this point, some of you gear heads know what’s wrong but for the benefit of those of you scratching your head, I’ll continue on with, a warning to all of you that this can happen to you! Last fall, before the weather changed, I installed a new spark plug. My Thoroughbred is equipped with the Truax cylinder head which requires a ¾” reach spark plug. I remember when I went to the local Napa Auto Parts store they did not have in stock the spark plug I use. The counter man offered me a different brand, claiming it’s the same heat range and exactly the same. When I installed this replacement, it started good and ran decent for a short time. After checking everything else that could possibly cause this condition, I took a hard look at the spark plug. It was not fouled but had some black soot. Not unusual with the poor performance. I thought about it and decided to go on line and try to identify the specs of this spark plug. When I found the manufacturer’s listing it jumped right out me! It was a resistor type spark plug. It’s a NO No to use a resistor or suppressor type spark plug with a magneto. While I knew this, I overlooked the possibility of the inter-change cross over by different brands of spark plugs. I had to special order the correct plug and last night, I started the bike and it ran great! So the moral of this story is to be sure your spark plug choice is the NO RISISTOR type. Fifty years ago, when these bikes were built, the resistor or suppressor type spark plugs were not invented yet. They came about later to prevent radio interference. I expect some of you to challenge the above and that would make a great discussion subject on the Forum! — Jimbo Degreasing at the Mustang Facility By Jim Cavanaugh, Mustang Motorcycles original Production Manager Reflecting back over the Gladden/Mustang days, I suddenly remembered how we degreased parts after we received them from the machine shops at the Colorado Blvd. facility. Out in the rear yard there was a small brick building about 12 ft. square and in it, a large steel open top tank. Below the bottom of the tank was a gas fired burner that heated the tank. A double walled system on the tank sides housed water (water jacket) which was heated over 212 Deg. F. Inside the bottom of this tank was a level of carbon-tetra-fluoride, about 12 to 14 inches deep, as I remember. The procedure was to place the parts to be degreased into this open basket which was connected to a rope, so that it could not be dropped into the solution. Now, here is the magic!. As you lowered the basket of parts, as soon as the parts were placed below the fluid level of the water jacket in the sidewalls, the grease would just run off like water. The parts became amazingly clean, instantly and very hot!. It was not necessary to submerge the parts under the CTC, just place them above the level. What I don't know is how the procedure affected the environment or "trickle" down problems or if the method is still used today. I never seen this again in my careers. We were constantly warned not to degrease used, oily engine or repair items which would contaminate the CTC. The aircraft division also used the same procedure. Another "flashback" — Jimbo Mustang in Nigeria - Late 50's By J. Baker Hill Greetings, I grew up in Nigeria where my dad was a missionary. Starting in 1956 for several years we owned a Mustang motorcycle. My dad used it to visit churches in the "bush" in places unreachable by car. We also used it for around-town transportation, going to the school where he was principal, the post office, etc. For these trips I would ride on the tank with my younger brother behind me, and eventually my second brother in a box on the luggage rack. The Mustang had a siren which was operated by kicking the horn back, causing the rubber-covered end of its shaft to contact the exposed flywheel and make a sound never before or since heard in the Nigerian town! When we drove into the garage, the Mustang was so loud we all rushed around to the front to push the kill button and shut it off! The Mustang died about 1959 when it threw a rod through the crankcase and was never repaired. On a visit back to our old house in 2003 I found the engine still sitting in a shed. I remember a lot about the Mustang even though I was only four when we got it and seven when it died, aided by some old slides we had. I eventually scanned the slides to digital and I attach them for your enjoyment. This particular day was when the two missionary families in our town found ourselves with a broken Land Rover and resorted to the Mustang and an attached red wagon to get to church! Upon reflection after writing the letter I remembered that I saw the cylinder and crankcase of the motorcycle on a trip back home (Nigeria) much earlier than I had stated. It must have been either in ’82 or ’88. When I went back in ’03 I don’t think I saw any of the parts of the Mustang lying around. It was located in Igede, Ekiti State, in southern Nigeria. I am sure that by now any parts that have not been melted down would be impossible to locate or identify. Once on a day after a rain we were riding with my dad and he lost control on a muddy part and went down. Fortunately we weren’t traveling too fast, but as I was sitting on the front of the tank I got the end of the handlebar in my gut; knocked the breath out of me but I was otherwise uninjured. My dad never rode it much after that and when it threw a rod he pretty much gave up on it. I never drove the Mustang myself (I was 7 or 8 when it died) but I remember once some friends came with a son who was around 6 years older than I, thus a teenager. After a brief verbal lesson he got on the bike and kicked it to life; then put it in gear and let out the clutch. Although the Mustang was probably not too powerful it did have a good bit of torque and took off with him. I still remember him powering up the hill from our house, screaming and forgetting of course to let off the gas! He finally came to a stop in some bushes without killing himself or hurting the bike. I don’t think he has ridden much since, either! Thanks for the help on ID’ing the Mustang. It’s nice to know a bit of information about it. Thanks very much J. Baker Hill What MMCOA Clube Members Think: • 1950's Mustang Pony Model 4. • Standard cylinder head, front wheel brake. • Large sprocket on the rear brake drum, along with the crash bars tell us it was a Shriner model. • Only 25 white ones were made, all 25 were originally sold to an El Paso, TX dealer for the Shiners. • No one has seen, or has any info on the horn. One Sweet Ride By Don Gillock I bought it on Ebay — Sept.9, 2002 from a guy in Kansas City, Missouri. He threw it in a pick-up and brought it to my house for free. It was a mess, didn't run very good, and had a rod knocking. I immediately found MMCOA and Jim Cavanaugh. With a ton of emails, we tore it down and fixed everything that was wrong with it. Got all my parts from Alan Wenzel, and he was helpful too. Alan didn't do email back then, so we used the fax machine a lot. He would send me parts with a bill. Then I would pay him. Who does business like that these days? It was great. I rebuilt the engine, straightened the frame that was bent, then dolled up everything else. It actually had a pretty good paint job and seat. I did some rechroming on rusty parts, and bead blasted the aluminum parts to make them look new. The tires were good too. It's a rider, not show quality, but it runs fine and is fun to ride. I have a bunch of build pictures as I went along. Jimbo and I brainstormed about how his build should be (see Jimbo's build in the Forum). Slight modifications here and there, not "factory", but determined "for the better". It's the street rodder in him. The Mustang is a simple machine, but talking to people that have been there and done that make the rebuild a lot more pleasurable. That is what I got from Jimbo. Of course now after five years, we talk about everything. I have seen him once at Paris, Texas and the rest is all email and pictures. Never let it be said there is no such thing as an email relationship. I would sure bet he shows up at the next nationals with a prize winning TB in his truck! — Don Gillock Mom Learns to Ride! By Jack Tennant When I was 17 years old I had a Mustang, I don't remember what model it was but I purchased it in1953 from a local dealer. This dealer, unknown to me, kept the owners manual. I suppose to make sure people came back to him for maintenance. Anyway, one day my mother asked me if she could ride my bike. I immediately said yes but she wanted to ride up the driveway towards the garage. I advised her not to do this but she insisted and so I let her. She got on the bike and had it in 1st gear and open the throttle and released the clutch, well as you might imagine she rode my bike right into the back wall of the garage because she was not familiar with it and she froze on. That bent the front forks. I worked at a Auto alignment shop at the time and so I had to take the forks off and get them back in shape with a hydraulic press. That worked and I never had any problems with the bike. I never allowed my mom to ride my bike again and she never asked, I suppose we both learned a lesson that day. Never let someone ride that is not experienced or familiar with your equipment. — Jack Tennant Ocean Springs, MS You're Fired! — Factory Story By Jim Cavanaugh, Mustang Motorcycles Production Manager One of the most serious ongoing problems with the production of Mustangs was labor turnover. I mentioned this before, I know but not in a specific detail. A good part of my time was training new employees the methods and use of tools to perform their contribution to the work assignments. No sooner than I had a new guy trained he would be gone, usually after receiving his first paycheck and the cycle would start all over again. One of the assembly jobs would be to install the upswept exhaust pipe. I would instruct a “newbie” when installing the muffler assembly, to always place the wooden 2 X 4 block between the rear tire and the vertical rear fender brace before drilling the retaining hole for the muffler, to prevent puncturing the tire & tube. I don’t know why the fender braces were not predrilled and they should have been. I would always warn them that if they ignore this procedure and drill into the tire, they would be fired on the spot. No warnings! This may seem cold and calculus but to rework a bike that is almost complete by removing the rear wheel assembly and replacing it, only slowed the team down considerably, not to mention scrapping a brand new tire and inner-tube. Too often, while doing my regular work, I would hear the old familiar “POW!”, a sound that was unmistakable. I had no choice. I knew what I had to do. I just would walk up to the employee and say, YOU’RE FIRED! FWIW! — Jimbo Editors Note: Although this story seems a little negative, remember this happened about 50 years ago. Times (and people) were tougher and working conditions were harsh by today's standards. Jimbo had to do his job, to keep his job. This does not mean he enjoyed firing people! This is a great account of actual Mustang History. If you drill a hole be sure to guard them tires! Thanks Jimbo! Sudden Stop Syndrome By Jim Cavanaugh, Mustang Motorcycles Production Manager During the many years I worked at Mustang Motor Products, I often had to view, inspect and repair, SUDDEN STOP engine damage. When this occurs on an aircraft engine usually, every reciprocating part must be replaced or Magna fluxed. With a sixty year old Mustang engine, it can be catastrophic. What is Sudden Stop Syndrome?(SSS) Sudden Stop syndrome is a condition whereby the engine, operating under load, suddenly stops without warning. What causes Sudden Stop Syndrome? • Insufficient motor oil in the engine • Oil pump failure • Prolonged over revving of the engine (6000 RPM plus) • Overheating (piston seizure) • Connecting rod failure (improper torque,stretched rod bolts, fit & clearance problem) What happens when the engine suddenly stops? Depending on engine speed when it suddenly stops, is relative to the engine damage. For example, say the rider was traveling at 45 MPH and the engine suddenly stops for one of the above reasons. Before the rider can depress the clutch lever, the rear wheel is already locked up and skidding. If the rider maintains control, he or she is lucky. The worst condition scenario would be that, while the engine stopped suddenly, the momentum of the flywheel did not stop quite as sudden, and keeps rotating, resulting in severe damage to the crankshaft keyway, usually not repairable. At the factory, we would just scrap the crankshaft. Perhaps Alan Wenzel has a repair procedure for this now. The flywheel keyway and hub usually are also badly damaged and beyond repair .The good news is, Alan offers replacement flywheels. Crankshafts are becoming very hard to locate and very pricy. What can I do to prevent this damage should my engine suddenly stop? The first thing you should do is remove your flywheel and carefully inspect both the keyways of the crankshaft and the flywheel. Remove the (steel) flywheel key and throw it away as far as you can! This steel key is what causes all the damage should you have a SSS event! If both keyways are in good condition replace the steel key with an aluminum one. If Alan does not offer an aluminum key, visit your ACE Hardware store and ask for a length of 3/16 square aluminum stock. It usually comes in three foot lengths. Just cut it to length. Now you have a life time supply or can share some with your Mustang buddy. THIS IS CHEAP INSURANCE to protect that almost irreplaceable crankshaft. THINK ABOUT IT! DO IT NOW! If you don’t have the proper flywheel puller or holder, contact Alan. I would also replace the flywheel retaining bolt with a new grade #8 cap screw and a new lock washer. FWIW! — Jimbo Sid Dickerson & his beloved Pony. By Sid Dickerson My Mustang pony was Galaxy Blue, a medium blue, almost metallic. My bike had an "Upswept" exhaust that put burns on many a girls leg. It did have a chrome luggage rack and "crash" bars but, I don't remember a chrome fly-wheel cover. Other equipment included a speedometer, front wheel hand brakes and a folding kick starter. It also had a wide saddle seat. There weren't many motorcycles in rural Arkansas in those days, just a lot of Cushman scooters. I am not totally sure, but believe that my father bought it for me from a young man, who had bought it from a guy driving through with two of them in the back of a truck. After a couple of years, he decided that he wanted a "big" bike and sold this one to my dad for me. That bike and I spent some great times out on back roads of Southern Arkansas without many mishaps. I had built a seat cushion to mount on the luggage rack so friends could ride around town. Once a friend and I were taking him to band practice and hit some loose gravel going around a curve. I saw that I couldn't control it so I went for the ditch. Ran down the ditch between a power pole and a street sign. When we went back, we could barely get the bike through pushing it! Never got hurt. Went down on ice a couple of times. I would just stick my leg through the crash bar and ride it down. I think gas was somewhere around $.23 a gallon, so that wasn't a problem either. Probably worked out to less than a dollars worth every couple of weeks. I've only got one photo of me sitting on it and it's not too clear. I had not remembered how low to pavement it was until running across this picture a week or so ago. — Sid Tarno By JIm Cavanaugh Mr. Tarno was hired while we were still located in the Colorado Blvd. plant before the Mustang group joined us. At the time, I was promoted to Foreman of the engine assembly division. Tarno, he liked to be called Tarno, at first was trained to build the many sub-assemblies before he took a position on the engine assembly line. At the time, we were producing mostly the industrial versions of the engines. Models 4 horsepower to 7.5 horsepower. Tarno was a senior citizen, in his early 70’s, completely gray and moved slow but his every move was very efficient. He loved to talk about his lady friends always bragging about his conquests. I don’t think many of us believed his stories but we had no reason to doubt them either. His work was excellent with no problems after his training. Soon he could take any position on the assembly line and build all of the sub assemblies which included the Mustang magnetos and the difficult rotor assemblies. The engine division was separated from other Gladden Products which was then dedicated to aircraft hydraulic and electro-mechanical products, by partitions. The engine assembly consisted of a very long room with a conveyor belt and an engine test cell for live testing of the completed engines behind a fire wall of this long room. Completed engines would actually enter the test cell thru a small opening in the fire wall. The engine assembly area was noisy with almost every station using air powered impact wrenches. Lots of activity constantly and maybe this is the reason Mr. Gladden only on rare occasions would have a walk thru. As I mentioned in a previous story, we always had an early warning of his visits because of his heavy French cologne, which would arrive before him…. On one occasion, Tarno was seated in a chair and assembling Mustang Magnetos at the assembly bench. Mr. Gladden frowned on anyone sitting down on the job, no matter for any reason. I mean this would make him furious! Of course, this was the day Mr. Gladden walked by. He immediately saw Tarno seated. Tarno had about 25 units completed and stacked up in a couple piles. Mr. Gladden walked over to Tarno and just watched him for a minute and never asked Tarno or me a question. He looked up and made sure we made eye contact and then I knew I was in trouble… The next day, thru my supervisor, I was instructed to deliver enough components to assemble 100 magnetos to the department next to ours. This department, mostly females assemblers mainly assembled small electro-mechanical items contracted by other companies. Yes, the girls were allowed to sit at their stations along a conveyor belt. I was instructed to train the girls to produce the unit systematically down the conveyer belt. This took several days including training a lead lady. Before leaving them, I made sure all knew their job. This was a time & motion study as all others with everyone clocking in and out of the job until completed. They already had the time study of Tarno from a previous job. About a week later, the mags were delivered to our department. They still had to be tested since the testing device was attached to our assembly bench. Tarno went to work! After testing the 100 units Tarno showed me the many rejections, most of which did not have proper voltage or amperage for the lighting system. After a meeting, it was decided to have our department repair the mags. We found later that Tarno’s time was 50% faster in his casual pace. We were never charged back for the work effort and no mention was ever made about our methods again. Mr. Gladden really thought his automated assembly department could be a better cost effective operation. But he really wanted to give me an object lesson. He just never liked me! Keep em’ rolling — Jimbo Burman Gear Boxes (The two edged sword) By Jimbo Every one knew that the Burman gear box was the life blood of Mustang. Certainly, the Burman management knew it. Most of the Mustang dealers knew it but not many knew the “trickle down” problems, The Mustang management had to endure the many quality problems that was a constant ongoing headache for me. I will start with a typical shipment from Birmingham, England. Usually by the time the merchant ship arrives we already are in short supply and getting the order through the US Customs Department was time consuming. It could take weeks! If the gear boxes are really urgently needed we could pay our customs broker a fee to get at least one crate released on bond, and the remaining boxes in due course. Usually one crate contained 25 units. We always requested that each unit be totally wrapped in a special heavy wax paper and to have suitable packing to protect the polished surfaces. The order called out that the shipment was to marked, fragile was to placed in the ship’s hold, NOT DECK CARGO. Too often, Murphy’s law kicked in and some of these important instructions were ignored. Unpacking the gear boxes was always an interesting event. They would be packed in excelsior which was curled wood shavings. This material would absorb moisture like a sponge. The worst condition scenario would be that the shipment was placed on deck, the packing was wringing wet from rough seas splashing on them and they did not get the wax paper wrap. This spelled big trouble for Jimbo!. On a brighter side, it was not unusual to find an envelope from one or more of the Burman female employees. Often with a photo of themselves, sometime a bit provocative requesting the finder, (me) to become their pen pal for the time being with the ultimate goal of romance, marriage and eventually US citizenship. This was always very entertaining and I would share the moment with others and have a good laugh. If the external surfaces, of the gear box was too corroded I would disassemble them and use most or all the parts for spare parts orders. If we were out of gear boxes at the time I would have to take the corroded parts to the metal polisher to be re-polished and of course, I had to reassemble them into usable units. I believe insurance claims were made and I would never know the outcome. I do remember that a job (project) card would be issued and my time or others would be tracked by time cards against the job. Too often another scenario would occur late on a given afternoon. I would be testing a bike, either a 3 or 4 speed model and either the kick starter or the gearshift lever, or both would not return to it’s home position. Oh No! It’s 3:00 Pm and I still have six more bikes to test and have crated. I put the bike onto (Jimbo’s quickie stand) and remove the kick starter cover. Sure enough, not enough endplay in either the kick starter shaft or the shift quadrant. I take the parts over to the R&D department to use the engine lathe to machine more clearance in both parts. Oh! Oh! Howard or Chuck is using the lathe. I go back to testing more bikes and will rework the troublesome unit last. It’s 4:30 now and I have to call the truck lines to pick up today’s shipments. Usually most go by one truck line Transcon. I race out to label the crates and go back to the R&D department. Oh good! The lathe is mine! This does not take long to machine and while waiting for the trucks to show up, I reassemble the troublesome unit and retest. To late to crate this one today. It will have to wait for tomorrow. As much as we would complain to the Burman management about these problems, it went on to deaf ears. The people in their assembly department would just pass these endplay conditions on by leaving the retaining screw loose and then they would pass inspection. On our end, we had to check the screws to be sure that the gear box would not leak. Sometime the 3-speed units would have a distorted pawl spring or the pawl itself would not have any endplay and bind, but these conditions were easy to fix. Another rare problem would be when the kick starter ratchet would fail upon first start up. If the ratchet teeth had a poor heat treat, the teeth would be brittle and break off. This would make Jimbo very unhappy because my foot and leg would come crashing down and hit the foot peg with enough force to twist my ankle. OUCH! — Jimbo |

Spontaneous Stupidity By Jim Cavanaugh, Mustang Motorcycles original Production Manager This is a true (untold) story of Chuck Gardner and yours truly, about a serious work related disagreement we had which escaladed over time with both bitter and sweet outcomes. I will relate the chain of events as best as I can remember them. This occurred while we were still located on Colorado Boulevard, in Glendale California about 1951. I should start by saying that all supervisory personal related to production was required to work at least a half day on Saturdays. This extra time was meant for supervisors to do the things that time did not allow during regular hours and to supervise any overtime employees. This strict rule was put in place by Mr. Gladden and policed by him. At this point in time, the Mustang division had already joined us at the Colorado plant. The Mustang assembly line and the Gladden engine assembly line shared the same long building side by side. The supervisor in charge of the bike building was a great guy named Eddie Arnold, not to be confused with Nobby Arnold, who also was on board at the time! Eddy and I had an arrangement that should one of us not be available on a Saturday, for good reason, that the other would take over both positions. This arrangement never happened often but worked well when one of us could not be there. At the time Chuck Gardner was in charge of all Mustang fabrication and the making of engine parts, including the cylinder block (Siberia) machining processes. On this particular Friday I told Eddy that I would not be able to be on hand Saturday. As usual he said “no problem, your covered”! I told Eddy that the engine crew would be working overtime all day Saturday because of a large order in process. “Thanks Eddy, I owe you one”! I declared. The following Monday morning this fiasco began! It seemed like a normal Monday until Chuck Gardner came storming up to me and said “I want you and all your crew to report to the engine block line”! I said why? He said” You were not here to supervise your crew Saturday so I had to send them all home”! I said Eddy was here to pinch hit for me because I physically could not be here”! He said” Eddy was not here either”! Well, I said that’s unfortunate and I’m sorry this happened but what has this got to do with my crew and I to work the block line”? He said “punishment, to teach you a lesson”! I said “The crew had nothing to do with this and as far as I’m concerned, I don’t report to you”! I refused to allow this and walked away. From that time, Chuck and I never talked to each other, completely ignoring each other for several weeks. On typical work days it was not unusual to meet in traffic on the way to work. I lived in the nearby foothills and Chuck lived north of the city and our route took us down Colorado Boulevard. It’s important to mention that Chuck drove at the time, a Crosley Hotshot, a very small open convertible with a very small single overhead cam engine. The engine displacement was small but Chuck had completely re-engineered the engine and it did quite well in the road race circuit, in his class winning often and he could drive! It was really a head turner when he put the “pedal to the medal”! I drove a 1941 Mercury, 4 door sedan that looked very innocent except for some larger rubber on the rear. Under the hood was what we called in those days a “3/8X 3/8 stroker, full race flat head with a Winfield 1A cam. It looked stock with stock heads re-chambered to Navarro racing head specs and a huge Lincoln carburetor on a stock manifold. My theme was to exhibit it as stock to the unsuspecting. It was also equipped with Lincoln transmission gears which had a huge wide gear ratio in first and second gears. 50 mph was no problem in first gear and 75 mph in second gear was a breeze. It was a little slow from a standing start but oh, would it come alive! Back then I “hung out” at a very popular neighborhood Ford flathead speed specialty garage and learned a lot early on. This day, some weeks later after our head butt, we both arrived at the intersection of Colorado and Brand Boulevards, the main busy two streets in downtown Glendale. We both were at the intersection waiting for the light to change to green and for some stupid reason(s) we both put the pedal down. Chuck jumped ahead of several lengths and then my Merc surged ahead. The next intersection was Central Avenue, another busy crossroad. We both slowed slightly and luckily, the light changed to green and off we were again! As I remember, I was slightly ahead of Chuck when we were approaching the Pacific Avenue intersection and again, we had the green light. The race was still on and the next stop would be the workplace, Gladden Products. As I recall, I was winning and in my jubilation, I noticed a bright flashing red light in my rear view mirror. You guessed it! A motorcycle cop pulls us both over! I could hear like a fox back in those days and I could hear Chuck arguing with the cop. I heard the cop tell Check that he notices Chuck leaving work every day and the loud exhaust noise and said “I should have given you tickets for excessive noise many times”. I avoided as much as possible talking to the cop. I just cooperated and tried to be polite. Needless to say, we were both written up for “speed contest”! After that Chuck and I still did not talk to each other on the job. I knew the fine would be very expensive and waited for two paydays before going to the city clerk. I forgot how much the fine was but I think it was over $200.00, a lot of money back then. So, I make my way to the courthouse and head for the window and low and behold, there stands Chuck in line in front of me! It was at that instant that we talked to each other again. He paid up as I did and then we had a discussion about how stupid it was and all the things that could have gone wrong. From that point on, our relationship improved and I believe we had more respect for one another. Some years later, Chuck became involved in a new career namely, the reactive co-polymer industry, making equipment like metering pumps and plural component spray guns to apply fiberglass and other reactive materials. Soon there after, he hired me to supervise the overall production. Then he did become my boss! We got along just great, complimenting each other and that would be another story for another time. Keep your “knees in the breeze! Jimbo 50 Years & Counting First Two Cycle Trips By Melvin Smith In 1956 my wife was giving a surprise baby shower for Vivian Moudy and wanted me out of the house that night so Paul and I planned an overnight trip to Warsaw, Mo. on our bikes. Paul had a Whizzer Motorbicycle and I had a Cushman scooter. Every thing went well till we were east of the Delmar Store and the rear tire went flat on my scooter. We took the wheel off and both got on Paul's Whizzer and took it to the Delmar store and patched it and we were back on the road. When we got to Warsaw we toured the town then got us a room at a motel that was just across the road from a skating rink. We had a good time skating and when we got back to the motel for some reason we thought maybe the bikes would get stolen outside so we rolled them in the motel room with us. The bikes gave the room a distinct smell of gas and oil but they didn't get stolen. We had a great time and decided that we should take a longer trip next summer. We both saved our money and the next spring we were able to trade our bikes for two brand new little Mustang cycles. They were exactly the same, bright red and just one number difference in the serial number. Paul gave me my choice and the one I picked was always the slowest, and broke down the most. They were built in California and had small disk wheels but they had a 3 speed foot shift transmission. They had a Tilton Carburetor and had a little button you pushed till gas squirted out then it would start on the first kick! It didn't even have a battery and had a Mag head and tail light, it was pretty dim idling but fine when you were up to speed. We got all the accessories available which included a speedometer, windshield, buddy seat, & a flimsy set of saddlebags. We bought them in Kansas City on 15th street just west of Prospect. When we started home with them the weather turned cold, we stopped at Peculiar and lined our pant legs with newspapers on the inside to help keep us warm. So for our trip we decided to ride them to Colorado and go up Pikes Peak. My Dad was not a cycle enthusiast and told us "When the break down just get out your map and figure how many miles you are from home and for $1.00 per mile I will come and haul you home” That was a lot of money in that time, we were only planning on taking $50.00 with us for the weeks trip and there were no credit cards then. We started off early one morning and expecting it to be real hot going across Kansas but it was cloudy and cold. Then we noticed a big black cloud and we were heading right toward it. We found a big barn along the road and we just got inside and the rains came, we must have been there a couple hours before it quit and we found out it had rained 3 inches. That was flat country and water was standing every where, we rode on in to a town, I think it was Hutchinson, Kansas and when we would run through standing water we had to pick up our feet to keep out of the water, the bike's flywheel was out in the open and would pick up water and get us wet anyway. We spent the night there and decided we were going to have to buy rain suits and they cost us $12.00 apiece and that made a big dent in our cash supply. We even wore the suit the next morning for warmth. We found the bikes were not made for cross country hard running, one of my motor mounts broke loose and we had to find a welder and get that fixed. Then I was leading and noticed Paul was getting further and further behind, I waited for him and we found his engine had a valve burned out and leaking compression. We made it to the next town and we found a friendly garage that had valve grinding compound and the deal to spin the valve in the seat and Paul is a good mechanic and was able to fix it where it ran good again. Then we had some trouble with my primary chain heating due to an oil leak that was to cool it but we were able to patch it up. We were able to find friendly garages to help us. We made it to Colorado Springs and could see Pikes Peak!! We serviced up the bikes and took off the windshield and planned to take the whole day to make the 20 mile trip to the top. The weather was beautiful and the bikes really ran good, the altitude didn’t bother them and they ran just as good at the top as at the bottom and we Really enjoyed the ride. The next day as we were putting the windshields back on some one told us if we took the baffles out of the mufflers we would have more power, so we left our baffles at Colorado Springs and sure enough they would run faster, little noisy but faster. We went up Look Out Mountain to Buffalo Bill’s grave. Then we went to the Garden of The Gods and the roads were not paved and had lots of red sand. I had been leading and when I couldn’t see Paul behind me I went back to check on him and he was standing beside his bike rubbing on it with a cloth and he had red sand all over his back and his arm was bleeding a little. When I rode up he said “The Little SOB Threw Me” I have never let him forget that statement and all our riding buddies also mention it to him now and then. In all the years & miles we have ridden since then I have never known him to have another accident on a bike. My granddad had taken me to Elitche’s Park in Denver and I wanted to see it again so we set out for Denver. There was a lot of traffic on that road and with our new found speed and not going against that west wind we really rolled that 70 miles to Denver, never thinking we were over 600 miles from home! When we got there Paul was tired so I made the run to Elitche’s Park by myself and I enjoyed it just as much as I did the first time I was there. We headed for home the next day and there was a Really big black cloud but this time it was behind us and going the same way we were. The wind got really strong but was going the same way as us and we could really go fast and when we put our hand up in front of the windshield it would fall forward the wind was so strong. We were doing fine and keeping ahead of the storm then all of a sudden the road went north for two miles and the dust & rain storm caught us before we could turn east again and we tried but there was no way to get ahead of it again. We made it to the next town and stopped for the night. The next day we were getting along fine and Paul was leading and all of a sudden my motor raced up and I lost power, the master link in my chain had busted and the chain fell off. Paul came back and decided he would take the chain back to the last town we had passed and see if he could get a new link. We decided there was no need for us to both go so I got a took a good nap under a tree waiting for him. He couldn’t find any chain but he was able to get a nail to put through it and the chain was long enough that it would fit with out the extra link. We were able to ride them on in home with out much more trouble and we already had plans for bigger bikes and a trip to New Orleans, LA but that is another story! —Melvin Cork's Mustang Story By Cork Marcheschi I had left my studio in Pacifica to grab a couple of sandwiches at Sam’s Deli but when I got there, Sam’s Deli had been spirited away and the sign read that a NEW deli would replace it. I liked Sam and his wife. This pair made sandwiches of integrity. Sam called every body BUDDY –male, female, young or old – you were Sam’s sandwich buddy. Maybe because Sam and wife were close to 60 or spoke with an accent or had never decorated, they had doomed themselves to the “upper middle class urban sprawl blues!” I felt a minor sense of loss; change at my age hits close to the heart. I walked down to the other sandwich place and on my way I was stopped by a powerful vision. I had to catch my breath – like an impossible jewel mounted on the asphalt was a 45-year-old Mustang motorcycle. If one of Victoria’s Secret models had parked next to it in a pink convertible, I wouldn’t have noticed. I am a collector by nature and art and art history have been my life. The pursuit and understanding of beauty in all its forms is my business and I stood thunderstruck by the little cycle/scooter/lawn mower engined piece of pure emotion and unique engineering. I was in love!!! Four years before this vision, I was interviewed on a radio broadcast. The show was about artists working in the public realm. I was completing a sculpture in a New Jersey rail station atrium. I was asked if I could be available for an interview on the site and I agreed. I spoke with the interviewer who would ask all five of the interviewed artist the same questions. No big deal, I do interviews well and am comfortable with a mic in my face. It all went fine till the last question, which she announced as “For a last question I always like to know if there is anything in your past that you have given up and would like to have back?” Before I could think my mouth dropped open and words that I didn’t speak exited my body: “My Mustang motorcycle from 1960.” I didn’t understand my own response until this moment in front of the Mustang parked in the Linda Mar shopping center. I wandered back to my studio without getting any lunch and thought about what I had just seen and how deeply it reached into me and found a place of great happiness. I was 12 years old in 1957; I lived in an Italian enclave on the east side of Burlingame, California. I had two passions in my young life. One was the rock n roll and rhythm n blues of the day, which was easy to access – 99 cents got me a 45 and KDIA played the tunes, so I was set. But #2 desire was more illusive: it had to do with movement and motors. I wanted a mini bike – I wanted something with wheels and a motor. I had watched other boys whose dad’s got them into 1/4 midget’s, and go-karts, but my dad wasn’t going to go there. Sad fact of the matter is my Dad and I never shared anything and we still don’t. My single focused passion was finally recognized by my mom. She watched me buy motorcycle magazines and read them cover-to-cover; she saw me use math trying to figure out engine displacement – I learned to read graphs from torque curve charts. My insistent pushing finally found a sympathetic ear in a distant cousin who lived in South San Francisco in another Italian enclave. The Gastone family had a son who had owned a 1946 Doodlebug. He had driven it till it wouldn’t go no mo’ and then it went into the chicken coop. Many years of chicken dust, chicken droppings, feathers and chicken feed made the scooter look like it had been resting on the ocean floor for 40 years. It was covered in poop and feather barnacles. It was beautiful! I excavated my wondrous little gem. My mom and I tossed it into the back of our stationwagon and it was mine. My mom – what she didn’t do for me – looked at the scooter as if it was the source of all disease but she saw the love in my eyes and closed hers. For the next week I cleaned the thing and for once in my life I enjoyed cleaning. Mr. Gastone remembered that it had stopped running because of something electrical. There is only one thing that is electrical on a Briggs and Stratton engine and that is the magneto. The guy across the street (Gino – another Italian) was a mechanic and he showed me how to test the spark. There wasn’t any so he showed me the flywheel/magneto setup and scratched a part number down and off I went to the power mower store. Gino helped me install the magneto and then showed me how to use the little kick-starter. Gino had a daughter; she was kinda vapid ( her name was Velma) and seemed to have no interests, other than B level movie magazines. I think Gino’s cottage-cheese-personalitied daughter helped him to understand something about the importance of this boy and mini bike moment. It was a guy thing! I can still feel the anticipation...kicked with enough force to toss myself over backwards...I didn’t feel a thing when my butt hit the concrete, because the motor started. Gino held the handlebars and laughed an appreciative laugh. I couldn’t believe it – the pop pop pop of the little engine had brought a smile to my face that was about to rip itself into my ears. There are not many moments in life that are pure joy but this was definitely one of them. I was blissfully happy – and now after 50 years I know how true and rare those feelings are. There were no brakes, no lights and definitely no license, so I was ready to GO!!!! And go I did – everywhere in Burlingame, San Mateo and the occasional field trip where my mom or grandfather would transport me and the BUG to a remote location. For three and a half years I rode that thing daily – IT WAS FREEDOM – I didn’t know a thing about freedom until the Bug rolled me down the street and I felt it. I didn’t understand that freedom had many faces and that you could feel free as an end in itself. When I was 15½ I could get a learner’s permit that would allow me to drive a motorcycle. I had been saving my paper route money for three years and I new what I was going to buy: a MUSTANG. The Mustang is the Unicorn of the scooter/cycle world for it is neither a scooter or a motor cycle. It is a unique statement of a wondrous moment in America. 1945 to 1965, the post war honeymoon that America had with itself. These 20 years were also the life of the Mustang. I found one for $80, a 1954 that had been owned by an adult who used it for transportation to his job at United Airlines. I didn’t know how to shift gears or use the clutch so Mr. Twissleman, the bike’s owner, taught me how to ride. I gave him 78 one dollar bills and 8 quarters, an hour latter I was on my way home. THUMP THUMP THUMP, a deep powerful sound that was friendly and serious at the same time had replaced the pop pop pop. Again I experienced large-scale joy. My hands tingled from the vibration; my butt went to sleep; but I was happy. The Mustang took me into San Francisco and as far south as Santa Cruz. I rode by myself and started to understand something about being with myself. The Mustang and I were very good friends. In 1963, when I graduated from high school and went to college, the Mustang was sold for tuition money. Over the passing years my love for motorized things on two wheels was alive and well. I never found much heart in the Japanese bikes, I always liked the British. I had several Norton’s and drove them cross-country. Great trips and never a breakdown (the Norton had an oil cooler and Mikuni carb – I had also lost the prince of darkness Lucas ignition for a Daytona electronic setup.) I had been busted at 14 years old for driving my Doodlebug at night without light and license. While the officer wrote up the ticket he told me in a stern but caring way, “You feel invincible now like nothing can happen to you – well one day that feeling may slip away and if it does you should stop riding.” In 1985 I was on a stretch of highway somewhere in Nevada, it was clear and sunny with no traffic on the road: I looked down at the asphalt as I had done hundreds of times before but this time I could feel myself hitting the pavement. I remembered the cop 28 years earlier and what he had said and it resonated with me. I never felt secure on my bike again. In 1986 I sold my last Norton. I had been teaching at the Minneapolis College of Art since 1970 and it was time to get back home to San Francisco, my parents were getting older and I really missed living by the ocean and the redwoods. So I sold my interest in my home, packed the trailer and drove my life back home, where I would be starting over. Back in my Pacifica studio I am asked about the lunch I was supposed to get and I had forgotten. I told the guys at the studio the story and they went back to see the Mustang. They returned with sandwiches and a lunch conversation circled about the SOMETHING that the little bike had. They had felt it too. I put forth the idea that the honesty and essential nature of the design separated it from most contemporary objects. The conversation continued but it took on the sound of voices in an aircraft hanger, the hollow reverberation grew as I receded further into my head. My experiences with scooters happened at a golden time, when freedom simply meant untethered movement. How elegantly simple and now how illusive. My attention finally return to the table and without any awareness of where the conversation was I drop in: “simple and easy are very different.” Simple is elegant, it is an understanding of what is necessary, it is toast with melted butter, it is a plaster wall that is smooth and plumb. Simple is what a thing is before it has been changed to what it is not. Simple is understandable and clear. Simple is achieved by honesty and directness of thought. Simple always bears the mark of the mind that saw the answer. Simple is not EASY and the two should never be confused. Easy is a step away from working or from thinking; easy can be a resulting solution of the awareness of simple or a consequence of simple. While pure EASY is relinquishing responsibility for knowing about what you are surrounded by. TV is EASY, and it infects its EZ into millions. Cars do all the thinking for you, you need not know anything about your car other than to watch the lights and do what they tell you to do. Most of us use computers but we are at their mercy if they choose to take a vacation. The lunch table was now quiet and I continued on. I understand that scooter. I looked at it and it was as if no time had passed since I last started one. It made me feel comfortable and nostalgic in a sleepy way. It made me want to run away from life and feel freedom again. Since that lunch I decided that a feeling that strong needed to be followed up on. I would sell a few of my Fauré enamel vases and replace them in my collection with a couple of Mustangs. I was going to find a Pony for my wife and a Thoroughbred for me. I packed up my two vases and away they went to Sotheby’s in New York. I then started to search for scooters. My first stop was the Mustang Owners’ Club out of Texas. The website was designed very well and worked great. I spent a couple of hours looking at the beautiful pictures and reading all of the info on the site. The bikes had the same quality as a well-designed tool. Their function was obvious from the design. You also understood that this little bike wasn’t a toy. I looked at these bikes for a long time and I looked at the men who restored and owned them. They were mature; at 62 years old I was probably in the middle of the pack. As I read it became clear that many of these were hothouse bikes. They were grown to perfection and then displayed as objects of great beauty and desire. I appreciated this Mustang as sculpture direction but for me I wanted to ride; I wanted to get on and go – go nowhere special just go! The Mustang Club website gave me an idea about prices and what to look for. With youthful fervor I did what I had done in the past I went to Craig’s list. I ran and ad looking for Mustangs, and sitting in bed with my daughter I tapped out my request and sent it into the mysterious electronic ether. The next day I got two hits. One for a Pony and one for a Thoroughbred. I called and asked questions then asked for additional pictures and both parties sent the pictures US mail. The Mustangers are not all on the information superhighway. I waited for the photos to arrive – try to remember sending some cereal box tops for a baking soda submarine and how long the wait was. In the meantime, I contacted the Mustang Motorcycle Club of America. I sent a note alerting the general mail box person that I was a writer and was going to write about my search for a Mustang and if this kinda thing rang any bells, I would love to hear from people. The next day Don Cook sent me a great note and welcomed me to the quest for the elusive Mustang. Don forwarded my note to Troy Harrison, the designer of the website and a Mustang owner. Troy was very friendly, open and willing to help. He passed on a few other names and so began a cascade of names and information. The little motorcycles had cast a spell on a group of men who had chosen to put energy, thought and quiet passion into them. The members of the owners’ club were keepers of a legacy that could have slipped away and possibly not even exist as a footnote in American culture – BUT due to the spirit of the Mustangs design that wasn’t going to happen now. I don’t think it matters what you love or are passionate about as long there is something!!! Extracting joy from contemporary life is a puzzle that many never achieve. Over the next couple of weeks I sent Troy pictures of possible bikes and he responded or sent them on to another member who would then respond. I love the search and gathering new information that is of no particular use except to lubricate my aging brain. I found a Pony that looked good and I liked the owner so we struck a deal. The next day I did the same with a Thoroughbred. One in Oregon and one in Pennsylvania. I hung up the phone after arranging to have the bikes shipped to me and inside my head I heard a scream: What the hell are you doing!@#$%^&*()? I had heard it before... I let the echo die down and got on with my life. The safe side of the street may be safe but nothing great happens unless you put yourself in risky situations. The Simple and Easy dichotomy continued to roll around in my head. Was I finally feeling the future push me out the back door? I remember the future that was presented to me as a child. The future was bright and shiny and it would free us from the drudgery of common work. The Futurama shows that toured America in the 1950’s and early 60’s were fun and the future was presented like an amusement park ride. Of course when we got to the place that THAT FUTURE was supposed to be we were very disappointed. So here I am in 2007, I have a cell phone, two computers, cable TV and use eBay. My life is harder than before I had this stuff. I don’t have more time that I can use in any meaningful way, I can’t fix my computer, I can’t fix my phone, I can’t fix my car. And many of the little things I could fix, I can’t open without destroying. I feel as though I am being asked to relinquish my relationship to the objects that surround me. The digital world asks me to surrender to it and I am not going gently into that dark night! I don’t want to sound angry because I am not. I am a curious observer who participates in the contemporary but brings six decades of experience as a filter. I get a call from Raoul – he is the truck driver that is going to deliver the Pony – WOW! I was excited – I was really excited. The next hour took forever but finally a 16-wheeler pulls up and out comes my yellow Pony. I had an adrenaline dry mouth the guys from my studio all came out and looked at the unique little bit of America’s past. The only thing left to do was ride it. I hadn’t been on a bike in 21 years. The last bike I kicked over was a British 850 cc twin. I had learned to put the bike on the center stand, balance my weight on both arms on the handle bars, lift my entire weight and then bring it down with a follow through action. I was able to start a 600 cc Matchless single with that technique. Well needless to say the little Mustang didn’t need that much coaxing and all that I managed to do with my over enthusiastic display was to put a bruise the size of a cantaloupe on my left leg directly behind my knee. I thought about starting my Doodlebug for the first time. A couple of more kicks and it fired up. I needed this. Since this sweet moment I have received my Thoroughbred and I have pulled the Doodlebug out of my dad’s basement. I am teaching my wife to ride the Pony, my 8-year old daughter to ride the Doodlebug and I love the TB. I look at all three of these bikes and there is comfort and reassurance in recognizing the bits and pieces. I ride by the ocean and up into the hills, The size, weight and power are perfect for a past midlife crisis. I am very happy that I traded French Art Deco enamel vases for something that has brought past joy back into my life. — Cork |

More stories to come - we have several to add. Please feel free to share your story with us, we'd love to share. ALSO this website is not part of the printed Mustang News so please send your story to:

MMCOA Newsletter Publisher (not affiliated with this website)

Robert Cantrell

1630 St. Louis

Springfield, MO 65802

(417) 862-2212

dlappin@cantrellbarnes.com

MMCOA Newsletter Publisher (not affiliated with this website)

Robert Cantrell

1630 St. Louis

Springfield, MO 65802

(417) 862-2212

dlappin@cantrellbarnes.com